The pneumatic probe converts the change of measured parameters into the change of air flow, pressure and other parameters, and is indicated on the gas momentum meter, so as long as all parameters that can be converted into flow, pressure and other changes by the pneumatic probe can be measured by the gas momentum meter. For example: thickness, aperture, shaft diameter, groove width, groove depth, fit clearance and other dimensional parameters, roundness, flatness and other shape parameters, hole perpendicularity, two holes or two axes parallelism, hole (shaft) center distance and other position parameters and can convert growth metrics such as volume, weight, force and other physical quantities. Therefore, if the principle and characteristics of various pneumatic gauges and the design method of pneumatic probe are mastered, almost all parameters can be measured by pneumatic gauges.

Model:E-MA4; Measuring range:±25μm,±50μm; Resolution:0.1/0.2/0.5/1.0; Total error:2%; Number of channels:Single; Measuring function:MXMNMNIAN-AMIN2

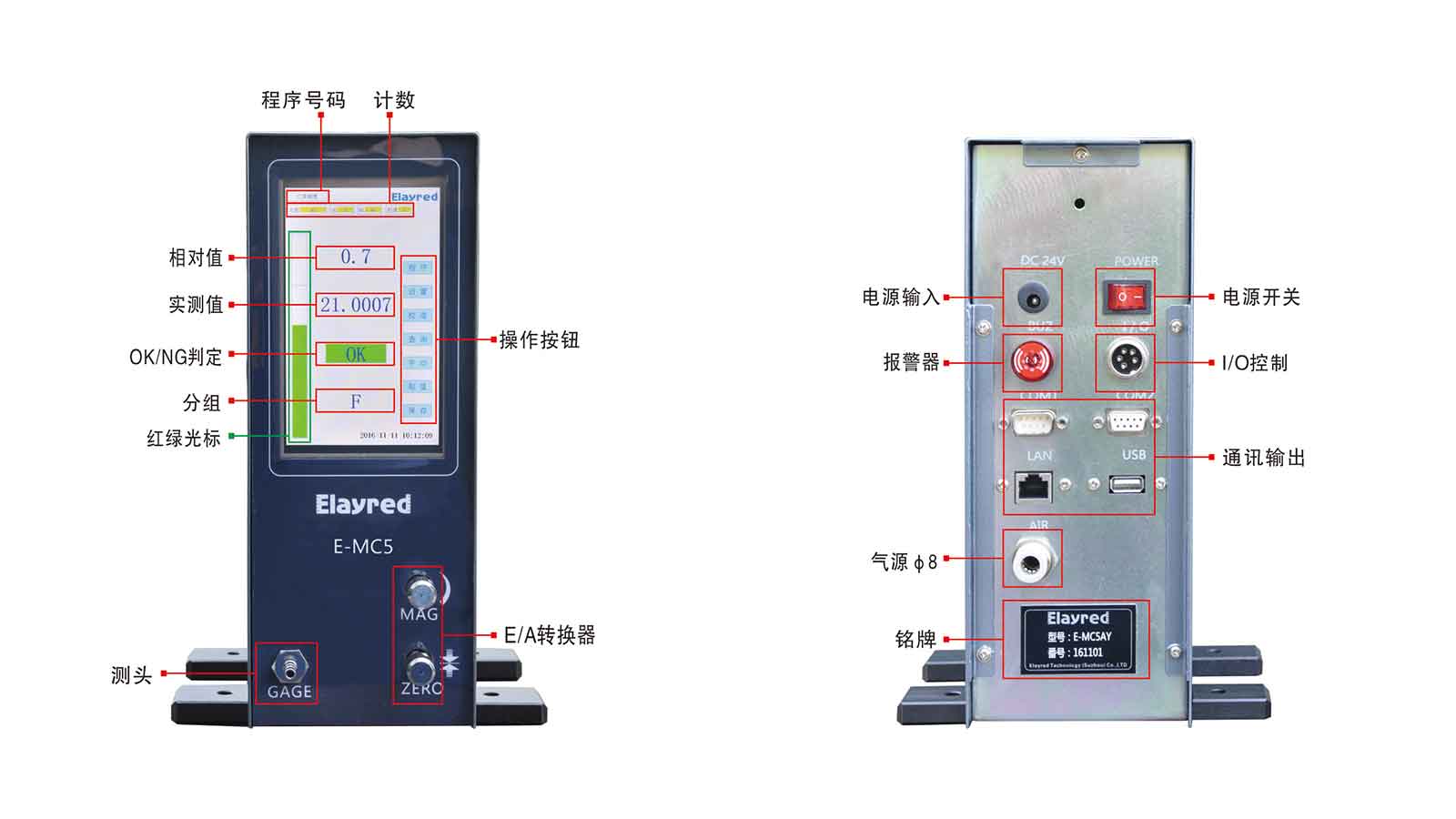

Model:E-MC5; Measuring range:±25μm,±50μm; Resolution:0.1/0.2/0.5/1.0; Total error:≤0.3μm; Number of channels:Single; Measuring function:MXMNMNIAN-AMIN2

Display screen:7Inch; A/E:EA-2; Accuracy:≤0.3μm Resolution:0.1/0.2/0.5/1.0 Unit:μm/mm/inch