The gas momentum meter is detected by comparison measurement method, and the requirements for the environment are not so high, and it can be used on the processing site. Due to the particularity of the gas detector, its probe is non-standard one to one, and the same set of probe is only suitable for the measurement of the workpiece of this size, and the gas detector can be universal. It is the non-standard one-to-one that makes the measurement efficiency of the gas meter particularly high, and the results can be measured in a few tenths of a second. The gas meter is suitable for rapid full inspection of large quantities, and the efficiency of final inspection of products is greatly improved, and its accuracy is also amazing0.1Micron, so it is particularly practical in the case of high-precision measurement, which is also an important reason why the gas momentum meter is widely used in modern industrial production.

Model:E-MA4; Measuring range:±25μm,±50μm; Resolution:0.1/0.2/0.5/1.0; Total error:2%; Number of channels:Single; Measuring function:MXMNMNIAN-AMIN2

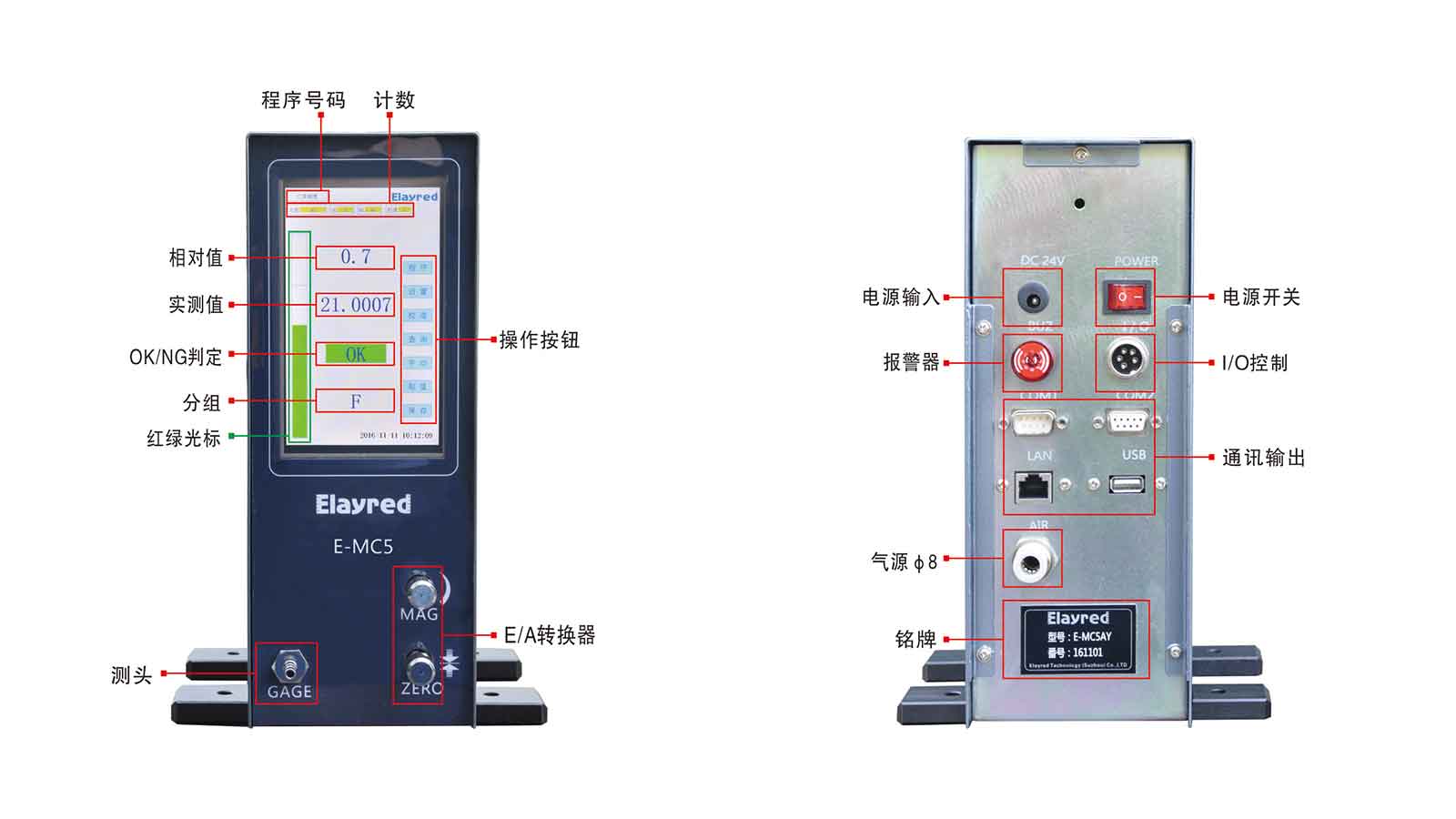

Model:E-MC5; Measuring range:±25μm,±50μm; Resolution:0.1/0.2/0.5/1.0; Total error:≤0.3μm; Number of channels:Single; Measuring function:MXMNMNIAN-AMIN2

Display screen:7Inch; A/E:EA-2; Accuracy:≤0.3μm Resolution:0.1/0.2/0.5/1.0 Unit:μm/mm/inch